|

| ................................................................................................................................................................................................................................................ |

| ˙INTRODUCTION OF MANUFACTURING PROCESS: |

|

|

|

|

|

|

|

| ................................................................................................................................................................................................................................................ |

| ˙THE FORGING PROCESS FOR LARGE DIAMETER TUBE SHEET.: |

| As part of the regular manufacturing process for large diameter tube sheet, forging involves pre-heating, shaping and solution heat treatment. Each workpiece requires a processing time of 5 to 7 days. |

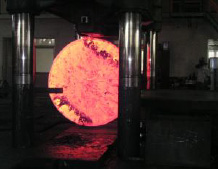

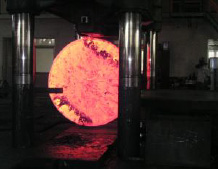

1. First of all, workpiece must be heated

to 1100 ° C to 1180 ° C in a forging

furnace |

2. Workpiece is removed and ready to

be

further processed |

2-1. Workpiece is shaped by hydraulic

press forging |

2-2. Press forging works by slowly

applying a continuous pressure or

force onto the workpiece. |

2-3. Workpiece can be deformed

completely, not only the surface, but

also the interior. Press forging can

be used to create the exact size

which is desired. |

2-4. Due to the constraint of oxidation to

the outer layer of the workpiece, the

level of microcracking of the

finished workpiece is minimized. |

3. Solid solution heat treatment upto

1060 ℃ is applied.

|

3-1. The heat treatment to be performed

is in accordance with the

requirements specified in the

applicable specification. |

3-2. Lastly, the workpiece will undergo

water cooling and UT inspection,

after solid solution treatment is

finished. |

|

| ˙FORGING AND SOLUTION TREATMENT: |

| What is forging and what is its function? The main concept of forging involves the shaping of workpiece using localized compressive force. |

|

(Press forging such as a hydraulic press machine can produce a blind tube sheet, which is continuous throughout the part, with outside diameter upto 3500mm.) |

(5 meter roll forging machine can produce a ring flange with outside diameter upto 4500mm) |

Forging uses the idea of hammer and anvil from traditional metalworking process. Forging can produce a piece that is stronger and durable compared to a cast or machined part. During the forging process, the workpiece is shaped, and its internal grain deforms to follow the general shape of the piece. As a result, the grain is continuous throughout the part, giving rise to a piece with improved quality and strength. However, production forging involves significant capital expenditure for equipment, and work hardening tends to occur from forging. Yet, the shape of the workpiece cannot be too complicated.

Forging: a process in which a material, usually metal, is heated and subjected to external compressive forces. It deforms and gives shape to the material. Forging is often classified according to temperature at which it is performed; cold forging and hot forging is widely known and commonly performed. |

|

|

| Solution treatment |

|

|

Solution treatment~ the forging furnace is heated to 1040 ℃ or higher(maximum efficacy is up to 1060 ° C) |

| |